Do you know some details of the paper bag machine

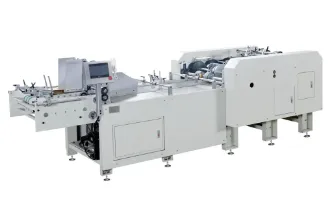

The paper bag machine uses printed single sheets as raw materials to automatically feed the paper and transport it through the paper conveying platform. Then use the front and side gauges to accurately position the single sheets and feed them into the crimping roller to press the vertical line. Then automatically brush the glue (hot melt glue can be sprayed), shape, automatically fold the edge of the organ, automatically form a tube, and then transport it to the bottom device via the push rod to pull the bottom, put the bottom glue, and form the bottom to complete the finished paper bag at one time.

The paper bag machine bag has high precision and fast speed. It is the best equipment for processing garment handbags and gift bags, and is your ideal business partner. The paper bag machine uses base paper or printed roll paper as raw materials, and seamless steel pipes can simultaneously complete square bottom paper bags with handles at one time. It is an ideal equipment for producing square bottom paper bags with handles.

The paper bag machine uses the handle assembly to make the paper rope and the patch roll paper into a handle, and then sends the handle to the sticking unit through the conveying device; in the sticking unit, the original color or printed roll paper is used for sticking After the position is broken, the patch position is glued, and the handle is automatically glued, the host machine will glue the paper with the handle, form a paper tube, cut, bottom indentation, bottom glue, bag bottom forming and conveying Out of the bag.